Cleanroom

The size of the particles in the air

Many of dusts are floating in the air and some tiny dusts, oily smoke, metal powder that could be checked with naked eyes and some particles that can't be verified by the naked eye. The size of particles are from 0.001um to 100um and it's spread broadly in the air. The size more than 10um could be checked by human's eyes and these kinds of dusts are too big to be removed from clean room and it need to be removed from the air conditioner. Sub Micron of which the size is less than 1um could be removed from clean room. The particle target cleanliness regulated by FED is 0.5 um or under and the below figures are showing the size of particles in the air.

Based on accumulated technology and pursuit of the perfect process management, materials management, construction management, safety management, personnel management, quality of construction and management.

Recently due to the development of high-tech industries such as electronic industry, precision machinery industry and its products are precision, miniaturization, high quality and high reliability is required. Electronic Factory, FILM precision machinery factory or factories, etc. resulted in the production of products suitable for the intended use, and the defect of the product is attached to the product being manufactured Indoor rich particulate hinder the reliability and yield of the product (cost of production) because they have a huge impact on a part of the action takes place the entire plant or important to maintain a clean environment for the need to respond to be.

Industrial Clean Room clean space for this purpose is called, often state that requires very high purity.

Industrial Clean Room clean space for this purpose is called, often state that requires very high purity.

ICR applications and features

| CR applications | Special Remarks | ||

|---|---|---|---|

| ICR | Electronic Industry | Semi-Conductor |

|

Print edition |

|

||

| Electronic Calculator |

|

||

| Artificial satellite |

|

||

| Bumak |

|

||

| Predision Industry | Precision Machines |

|

|

| Optical Machines |

|

||

| Clock |

|

||

Closest to prevent product contamination, spoilage protection and to prevent infection of patients with aseptic pharmaceutical factory, food factory, hospital operating rooms, etc. of the status is required.

General caught up in a high-performance Filter removes bacteria, but viruses compared to bacteria very much because it is difficult to remove by itself. However, most of the bacteria or virus, so the presence of suspended particulate matter in the air attached to the particulate matter in the air by removing the fungi also can be removed. Sterilized by use of drugs, such as ultraviolet radiation or lithium chloride to remove the bacteria in the air that usually, but in recent years through the high-performance Filter sterile closer to purify the air by the state can be obtained.

We call it as Biological Clean Room which is the clean space for this purpose.

General caught up in a high-performance Filter removes bacteria, but viruses compared to bacteria very much because it is difficult to remove by itself. However, most of the bacteria or virus, so the presence of suspended particulate matter in the air attached to the particulate matter in the air by removing the fungi also can be removed. Sterilized by use of drugs, such as ultraviolet radiation or lithium chloride to remove the bacteria in the air that usually, but in recent years through the high-performance Filter sterile closer to purify the air by the state can be obtained.

We call it as Biological Clean Room which is the clean space for this purpose.

BCR applications and features

| CR applications | Reason for the need of the CR | Special Remarks | ||

|---|---|---|---|---|

| BCR | Drug-related | Drugs |

|

|

| Experimental effects |

|

|

||

| Food and Cosmetics |

|

|

||

| Bio-HAZARO |

|

|

||

| Hospital | BCR operating room BCR Hospital |

|

|

|

| Neonatal intensive care unit ICU Others |

|

|

||

Clean Room airflow rate indicates that the general rules on the selection.

Airflow rate (1) Average speed (m / sec or ft / min), or (2) number of hourly ventilation (number / hour) regulations.

Clean Room airflow rate(IES-RP-CC012/Table1)

| Class display | Airflow form | Average airflow rate | Hourly ventilation |

|---|---|---|---|

| M7 & M6.5 (Class 100,000) | NM | .005-.041m/sec(1-8ft/min) | 5-48 |

| M6 & M5.5 (Class 10,000) | NM | .051-.076m/sec(10-15ft/min) | 60-90 |

| M5 & M4.5 (Class 1,000) | NM | .127-.203m/sec(20-40ft/min) | 150-240 |

| M4 & M3.5 (Class 100) | UNM | .203-.406m/sec(40-80ft/min) | 240-480 |

| M3 & M2.5 (Class 10) | U | .254-.457m/sec(50-90ft/min) | 300-540 |

| M2 & M1.5 (Class 1) | U | .305-.457m/sec(60-90ft/min) | 360-540 |

| M1 Cleaner | U | .305-.508m/sec(60-100ft/min) | 360-600 |

(U=Single direction of flow , N = Non Single direction of flow M = interflow)

1 Typically used in a single direction of flow (laminar flow) if the average airflow rate.

2 Number of hourly ventilation is calculated by the following equation.

Hourly number of ventilation [count / hr] = average airflow velocity (m / sec) x discharge area (㎡) x3, 600sec interior volume (㎥)

1 Typically used in a single direction of flow (laminar flow) if the average airflow rate.

2 Number of hourly ventilation is calculated by the following equation.

Hourly number of ventilation [count / hr] = average airflow velocity (m / sec) x discharge area (㎡) x3, 600sec interior volume (㎥)

| Item | Contents |

|---|---|

| Doorway | Entrance and the Exit need to be the minimum and need to think separately. (Especially when installing the Air Shower) Avoid to contact the outside ( air rakrum) Locating to downstream ( Especially cross -floor) |

| The dressing Room | It must take a lot of the air content of the dressing room. Attached washbasin, and preparation of drink if a lot of people. Must be at least double doors between the Clean Room (Air Shower devices installed) You must enable communication with the internal If you need a break seal must be installed. |

| Export, import | Use the pass box (parts) as much as possible. Half to attach the inlet (large unit) |

| Interior layout | Minimize. Simplicity. Placed on the outside of the administrative office. Considering the contact method. Expansion plans People's movement to a minimum. Work location and wind direction of purifier Rash measures to the cubicle, local exhaust Return Duct work. |

| Indoor facility | Wiring, Pipe Duct exposure to a minimum. Ceiling lighting fixtures inside Emergency exits, fire alarms, fire extinguishers, power outages, toxic gas Intercom, telephone Cleaning Particle concentration, temperature, and humidity record |

Fed.Std.209E Class distribution

* The upper limit of the Class, each Class will be the name. Upper limit of the mouth more than specified concentration (per unit volume is expressed as the number of particles).

Fed.Std. Major revision of the 209E

| Items | Contents |

|---|---|

| Unit | Combination Miter law and British units, mainly recorded |

| Class displays | The number of particles larger than 0.5 ㎛ Class X and 10 / ㎥ display. To display Miter law, M was added. For example, the 209D in Class 100dms 100P/ft ≒ 10 P / ㎡ and Class M3.5. |

| Class classification | Higher purity than the 209D Class 1 Class M1 and Class 100,000 Class M7 has lower purity than |

| Microparticles Instrumentation | Instrumentation, and enables the use of CNC measuring particle diameter more than 0.02 ㎛. In this case, display the Class U (X). U = Particle measurement sign. X = the maximum allowable concentration of particles P / ㎡ |

| Standard measure particle | 0.1, 0.2, 0.3, 0.5, 5 Micron, one might want to use the other particle diameter. |

| Sampling | Concentration of particles by different sampling flow measurement instrumentation in place, even good, but ea / unit volume will be displayed. If the sampling point more than 10 locations, the simple average of the measurements would work. Class M2.5 higher purity than continuous sampling, in order to shorten the measurement time, continuous samplings may work as well. |

| Supplement | 209D of the relevant specifications, for coming, and delete isokinetic law, Ultrafine elementary particle concentration measurement method, a series of Class M2.5 higher purity than 3 items of the sampling method is added. |

| Class displays | Class upper limit | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|---|

| 0.1㎛ | 0.2㎛ | 0.3㎛ | 0.5㎛ | 5㎛ | |||||||

| Unit volume | Unit volume | Unit volume | Unit volume | Unit volume | |||||||

| Miter law | Britixh units | (㎡) | (ft3) | (㎡) | (ft3) | (㎡) | (ft3) | (㎡) | (ft3) | (㎡) | (ft3) |

| M1 | 350 | 9.91 | 75.7 | 2.14 | 30.9 | 0.875 | 10.0 | 0.283 | - | - | |

| M1.5 | 1 | 1,240 | 35.0 | 265 | 7.50 | 106 | 3.00 | 35.3 | 1.00 | - | - |

| M2 | 12,400 | 99.1 | 757 | 21.4 | 309 | 8.75 | 100 | 2.83 | - | - | |

| M2.5 | 10 | 35,000 | 350 | 2,660 | 75.0 | 1,060 | 30.0 | 353 | 10.0 | - | - |

| M3 | - | 991 | 7,570 | 214 | 3,090 | 87.5 | 1,000 | 28.3 | - | - | |

| M3.5 | 100 | - | - | 26,500 | 750 | 10,600 | 300 | 3,530 | 100 | - | - |

| M4 | - | - | 75,700 | 2,140 | 30,900 | 875 | 10,000 | 283 | - | - | |

| M4.5 | 1,000 | - | - | - | - | - | - | 35,300 | 1,000 | 247 | 7.00 |

| M5 | - | - | - | - | - | - | 100,000 | 2,830 | 618 | 17.5 | |

| M5.5 | 10,000 | - | - | - | - | - | - | 353,300 | 10,000 | 2,470 | 70.0 |

| M6 | - | - | - | - | - | - | 1,000,000 | 28,300 | 6,180 | 175 | |

| M6.5 | 100,000 | - | - | - | - | - | - | 3,530,000 | 100,000 | 24,700 | 700 |

| M7 | - | - | - | - | - | - | 10,000,000 | 283,000 | 61,800 | 1,750 | |

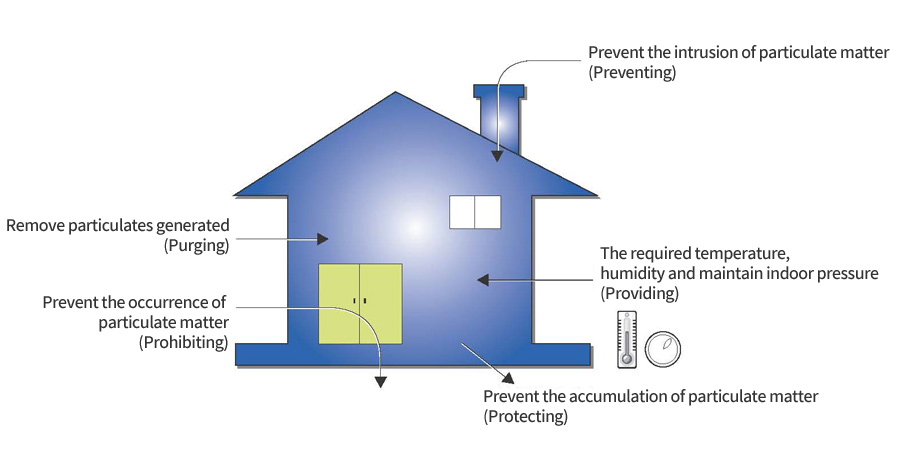

In order to efficiently use and maintain clean product, it needs to be in compliance with the followings.

| The basic principle | Considerations | Precautions |

|---|---|---|

| Preventig | Indoor air pressure | Maintain silgan adjust the differential pressure, positive pressure adjustment, the introduction of other skills |

| Architectural motion plan | Crew logistics, raw material, dividing the motion lines for each | |

| Distinction of clean station and polluted station | ||

| Air Lock, Air Shower installation | ||

| HEPA Filter | Filter Leak Prevention | |

| Prohibity | Personnel management |

Control the In & Out of personnel necessary and minimize the motion line of workers |

Dress management of personnel |

Wear clean gloves, sterile, human respiratory airflow blockage | |

| Materials, building materials for interior | Use materials surface processing, and non-oscillation | |

| Proteetig | Indoor airflow | Outlet location adjustment, laminar wind speed and adjust the recovery ventilation |

| building materials for interior | Uninterruptible interior materials used, Corner Mould | |

| Interior cleaning | Sustainable conducted according to the cleaning standards | |

| Purgiry | Clean Room Method | An accurate grasp of the facility uses |

Indoor airflow |

Air distribution vents and the expected location of rash | |

| Ventilation recovery | Maintaining a high number of ventilation | |

| Providing | Thermo-moisture-proof System | Constant temperature room, damp cellar, considering the calorific value of the operations personnel and production equipment |

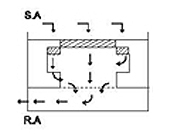

| Items/System | Vertical Laminar way | Horizontal Laminar way | Turbulent manner | Clean tube style | Tunnel approach |

|---|---|---|---|---|---|

Cleanliness |

Clean 1~100 | Clean 100 | Clean 1,000~100,000 | Class 1 | Class 1~100 |

Clean status while working |

Effects are less from workers | Upstream affects downstream rash | Affected by worker | No affection from the workers | The least affection from the workers |

The initial investment cost |

High | medium | low | low | medium |

Operating costs |

High | medium | low | low | medium |

Remuneration |

Easy | difficulty | Easy | difficulty | difficulty |

Maintenance |

Easy | Easy | Easy | difficulty | Easy |

Scalability |

difficulty | difficulty | 가능하다 | difficulty | Easy |

Precision Control |

It may occur when indoor airflows are imbalanced for controlling the whole rooms | The upstream affect the downstream flow oscillation | Existing the Imbalance | Maintain the high cleanliness | More precise control is possible than workload. |

System |

|

|

|

|

|

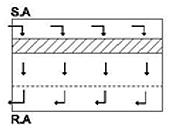

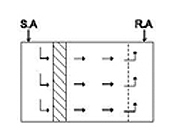

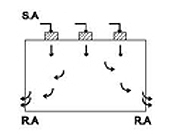

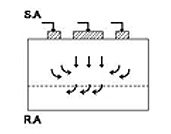

Patterns of Air Flow

Patterns of Air Flow

Laminar expression (vertical, horizontal) turbulence equation, and soul - flow, tunneled, and the characteristics of each, determined by considering the intended use.

Laminar expression (vertical, horizontal) turbulence equation, and soul - flow, tunneled, and the characteristics of each, determined by considering the intended use.

Cleanliness Level

The cleanliness of clean room is to be decided by the extension of each products requirements.. Cleanliness level is achieved by examining the number of the airflow method, ventilation, indoor pressure enough

Plan (Lay-out)

Considering workability, determines the lay - out to meet the cleanliness.

Isolate dust required job from other work.

Also recommends to consider people , stuff of entrances, driveways, utility, maintenance, comprehensive and regurgitating.

Isolate dust required job from other work.

Also recommends to consider people , stuff of entrances, driveways, utility, maintenance, comprehensive and regurgitating.

Structure & Materials

A smooth interior surface, the airflow is disturbed or do not allow dust to accumulate in the structure.

As well as the small dust particles are not attached, the material is easy to clean.

Work with the materials with moisture resistance, chemical resistance, chemical resistance could be used depending on the working contents.

As well as the small dust particles are not attached, the material is easy to clean.

Work with the materials with moisture resistance, chemical resistance, chemical resistance could be used depending on the working contents.

Adjuncts (Equipments)

Cleanroom ambient pressure maintained for dust control, air shower (for man entry and exit), pass box (stuff allowed for), safety damper (indoor pressure adjustment) for the storage and packing of the device screen Stow car. Clean lacquer.

Thus, each feature must be fully understood.

Thus, each feature must be fully understood.

Management of people and goods (control of working persons and materials)

Goods imported from outside and the worker, these are the major cause of a rash.

Wujin clothing and makeup of problems, including the basic knowledge are required for the cleanroom worker.

Wujin clothing and makeup of problems, including the basic knowledge are required for the cleanroom worker.

Utility

Water Supply District, a way for devices such as gas, electricity, energy supply, airflow, taking into account the lay out of fiexibility and need to be determined.

Maintain cleanliness, we need to be careful , not to be decreased.

Maintain cleanliness, we need to be careful , not to be decreased.